So you’ve got your 3D printer, spool of PLA printer filament, and SLT files from Thingiverse all set up. You’re ready to print those stylish cups and wacky kitchen utensils. But wait, is PLA food safe?

Yes, PLA is food safe, but not for long-term food storage. When it comes to 3D printing, keep in mind things like bacteria buildup, food safe coating and sealant, chemicals and production process, food contact time, and how the objects are cleaned.

A PLA study published in the Food and Chemical Toxicology journal that followed FDA (Food and Drug Administration) guidelines concluded “PLA is safe and ‘Generally Recognized As Safe’ for its intended uses…[to] hold and/or package food.”

I’ll also take a look at other popular 3D printer filament materials that are food safe options: PETG, HDPE, PP, and HIPS.

First, to better understand the food safety of those printed cups, forks, and spoons, we need to first understand what PLA filament is.

What Is PLA Filament?

PLA, or Polylactic acid, is a popular 3D printing material favored by users worldwide because its made from natural materials.

PLA filament is a plastic material that is corn based – meaning that it is derived from organic biodegradable material, with cornstarch being one of the most common materials that make up the bulk of PLA production worldwide.

It’s a thermoplastic aliphatic polyester (basically meaning biodegradable) that is one of the most popular materials used in additive manufacturing processes.

Oftentimes, one of the first few projects that users create on their new 3D printer would be some sort of mug or a shot glass of some sort. As users become more experience with 3D printing, they’ll begin to make miniatures, figurines, and even cosplay costumes and props.

The organic foundation makes PLA biodegradable and compostable – making it great for printing food-safe objects and kitchenware such as coffee mugs, shot glasses, plates, bowls and pet food dishes.

PLA has been widely adopted by the food industry to produce food packaging – substituting plastics that are made from fossil fuels as those are harmful to humans.

In recent years, there are several versions of PLA that have been developed over the years, with aluminum, wood fibers or even bronze particles becoming more commonplace as a component of PLA filament during production.

Compared to ABS (Acrylonitrile Butadiene Styrene) which is another popular non-toxic plastic, PLA is more heat-sensitive and more fragile, with a glass transition temperature (aka melting point) of about 150 ºC (300 ºF)

However, one of the great things about PLA is that the material itself is less prone to contracting during cooling – giving it a lot more geometric stability. That allows for more precise 3D printing of objects with detailed and defined shapes.

PLA is processed via injection molding, casting, blown film, thermoforming, extrusion and fiber spinning methods which makes it highly flexible, versatile, and easy to work with.

First, the lactic acid that naturally occurs in bacterial fermentation of vegetables such as corn, sugar cane or cassava is mixed with enzymes and heated, breaking down into D-glucose. This raw component is then polymerized and turned into PLA filament to be used in a wide array of applications.

PLA Advantages

When it was first discovered in 1932, the very first users of PLA material were companies in the biomedical industry. Because of the compostable nature and bio-based production of PLA, it has the ability to be absorbed in the body biologically – and takes between 6 months to 2 years to break down inside the body.

PLA is made from renewable materials, which means crops that grow naturally in soil. When growing the plants and vegetables necessary for PLA filament production, it reduces the carbon footprint as compared to other plastic products a couple ways:

- The crops absorb carbon dioxide CO2 from the atmosphere when they are being grown

- Greenhouse gas emissions and reliance on fossil fuel energy is significantly lower during PLA production when compared to other plastics that are fossil-fuel based

During production, PLA is easier to work with and requires less heat (therefore, less energy) to shape and transform into objects. It’s lower melting point compared to other plastic materials on the market makes it popular in 3D printing circles worldwide.

When PLA comes to the end of its usable lifetime, it is 100% compostable and emits a significantly lower amount of toxic fumes than other plastics when incinerated.

For food packaging use, food contamination is not a problem with PLA, while for biomedical use, PLA breaks down into a non-toxic acid in the body, making it safe for procedures.

PLA Disadvantages

A major consideration about using PLA filament material for 3D printing is the price. PLA is more expensive than other plastics that are fossil-fuel based products. Potential users reconsider the economics of using it over other materials rather than the helpful impact it has on the environment.

The agricultural impact must also be taken into consideration during the raw materials gathering process of making PLA. Overuse of fertilizers and GMO (genetically modified organisms), in addition to the potential clearing of natural habitats to make way for crop fields may result in more bad than good for the environment at large.

There is concern that PLA may be unsuitable for high temperature applications. On especially hot summer days PLA products have shown signs of deforming when in prolonged contact with direct sunlight.

Because PLA is made of organic materials, it has higher permeability than other plastics. Moisture and oxygen will possibly be able to penetrate through PLA. That leads to food spoilage, so it’s not advised to use PLA for long-term storage of food products.

At the end of its life cycle, PLA can be composted, however this compost is specialized and needs to be done in a controlled commercial environment. That requires an additional investment to the process.

The compost also adds no nutritional value to the soil, as once it is processed, it becomes inert and the beneficial organic properties of its natural components are lost.

Another issue is that of recycling. As PLA has a lower melting point than other plastics and cannot be recycled together. That doesn’t allow for economically viable recycling methods and may end up costing more to recycle per unit.

Current PLA Products And Use Cases

As one of the earliest adopters of PLA filament, the biomedical industry has been one of the oldest users of this plastic material due to its biodegradable properties.

PLA is also biocompatible with the human body and causes minimum infection or inflammation. PLA-based biomaterials are an exciting direction in the orthopedic medical industry.

Biocompatibility makes it highly popular in the manufacturing of bone fixation devices such as plates, screws, surgical meshes and in other applications such as drug delivery systems in the body.

One of the most widely researched technologies in the biomedical industry today is the use of PLA in tissue engineering. That may prove to be effective in treating issues such as tissue loss in patients.

The construction industry has also adopted PLA material in the manufacturing of insulation foam and carpet fibers. However, due to the biological nature and known brittle qualities of PLA, its use is only limited to products and processes which are not integral to the structural integrity of a construction project. We don’t want our buildings falling down.

Cosmetics and Textiles companies have increasingly looked to PLA as an alternative, eco-friendly material to be used in packaging and production. Because of its biodegradable and sustainable qualities, PLA may prove to be one of the biggest players in these industries in the coming years with the growing eco-conscious consumer market.

Lastly, the food packaging industry has reaped the many benefits of PLA in recent years. PLA has a GRAS identification (Generally Recognized As Safe) – meaning that it is safe enough to store food.

According to an experiment conducted by experts in plastic polymer production, PLA has been proven to release small amounts of lactic acid onto the food that comes into contact with it. However, the amount of lactic acid is largely insignificant, being about 700 times less concentrated than the lactic acid intake of breastfeeding infants.

How Does PLA Compare with Other Plastics

ABS – A material like ABS is known to release harmful toxic chemicals into your food, so it is best to avoid it at all costs.

PET (polyethylene terephthalate) – The most commonly used plastic in the food packaging industry. PET is easy to produce, widely commercially available and recycling plants for PET are available in many places around the world.

PET is found in soda bottles, condiment containers and packaged food from any food or beverage company you can think of.

With that said, the production process of PLA uses up to 65 percent less energy than the production of conventional plastics like PET or ABS.

PLA provides a lower environmental impact, but also raises the risk with food contamination. Let’s take a look at how to keep PLA 3D printing as safe as possible.

Food Safe 3D Printing Considerations To Keep Safe

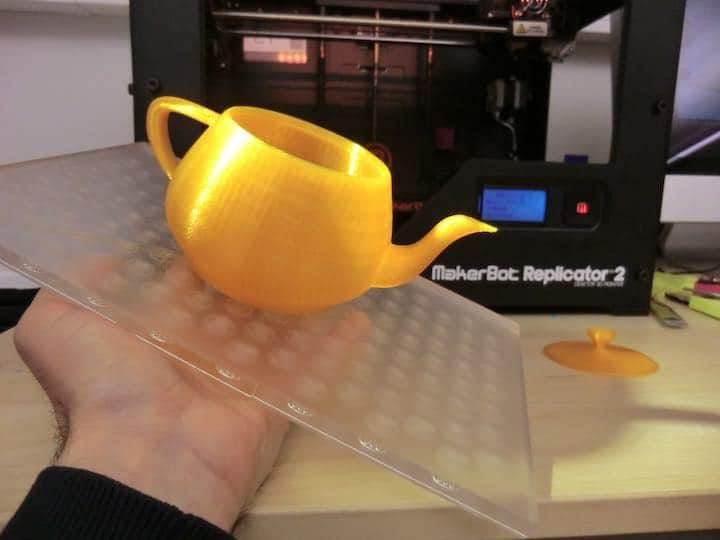

Although PLA is food safe and is starting to become more widely adopted in packaging of food products, there are a few things to take into consideration. Here’s a video showing a 3D print of a tea cup using the Cube 3D printer:

Here are some examples of the major factors to take note of for your 3D printed items :

Bacteria Buildup

Because PLA is organic, it’s porous in nature and may contain minuscule cracks that’re naked to the human eye in even the best looking printed objects.

These cracks are where germs and bacteria from old food can get lodged in, and they can flourish if not cleaned thoroughly. Keep an eye for smooth material as that can help prevent food getting stuck in your object.

It’s recommended that PLA is only used for disposable cutlery and kitchenware applications – if you’re planning to reuse your PLA kitchenware, then you might want to reconsider whether your 3D printer is the right tool to use.

As food items such as eggs or raw meat are more prone to harmful bacteria, it is recommended to not use PLA to store such items.

Food Safe Coating and Sealant

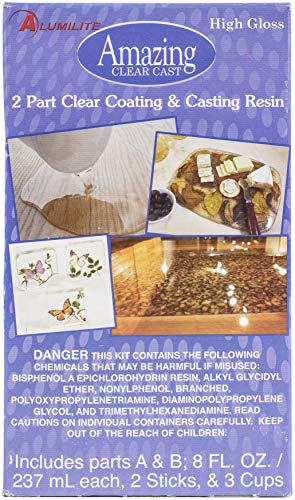

If you 3D print an awesome fork or other utensil and want to use it, you’ll want to use a food safe epoxy or sealant. The food safe sealant will reduce the risk of harmful bacteria infecting the food and the person eating or drinking by covering the tiny cracks.

The coating prevents the germs and bacteria from going into the tiny PLA cracks and becoming trapped. There also might be some fin

Polyurethane is the most widely used material for such a process and is easily bought at most DIY home improvement stores or on Amazon. It’s a similar process to using finish sealant to coat and seal wooden kitchen utensils and tables.

You’ll want to look for FDA certified Food Grade epoxy resin like the Alumilite Amazing Clear Cast Resin.

Chemicals and Production Process

PLA itself is made out of cornstarch – making it biodegradable and ultimately safe for food.

However, different manufacturers add varying levels of non-organic additives to the filament to change the features – color, strength, smell, etc. You’ll want to keep an eye on chemical properties.

3D printers may also emit some ultrafine particles that can be hazardous to your health if injected. You should be able to fix that during finishing and washing.

Those additives may reduce its food safe qualities significantly so it’s best to check with each manufacturer about the additives before you commit to a purchase of their filament.

3D printing models might also have hot ends that contain dangerous chemicals. So even if you have safe PLA Filament, there might be tiny particles that are mixed in with your PLA when you print. The safest option here is to look for nozzles that are made of stainless steel, like these Ivelink M6 nozzles:

Food Contact Time

How long your 3D printed object will come into contact with food will also play a factor into how food safe your kitchenware might be.

Items such as knives do not touch your food for a long period of time, so even without a food grade filament, these objects are safer to use on food.

However, if you’re thinking of 3D printing a food container like bowls or a coffee mug, you’ll want to take extra precautions with the food safe sealants and epoxy to prevent bacteria growth.

Dishwasher and Cleaning Procedure

As PLA is susceptible to high temperatures and is quite brittle on its own without any additives, most dishwashers will certainly cause your PLA utensils to break, melt or at least start to deform.

That ultimately leads the PLA objects to be unusable after a few cycles in the dishwasher. The breakage of these utensils during washing may also cause damage to your dishwasher and the other items being washed.

PLA plastic isn’t like the polycarbonate plastic used in many food containers for sous vide cooking and restaurant food storage.

The best way to clean your PLA utensils is by hand, with antibacterial soap and under lukewarm water.

Other 3D Printing Material Options That Are Food Safe

Other than PLA, there are several other safe materials that are known to be food safe for health effects. They are listed below:

PET (Polyethylene Terephthalate) / PETG

Widely popular and the most commonly used is PET, which has been FDA approved for a while now. PET in its base form isn’t used in 3D printing. You’ve probably seen or used it’s cousin, PETG, where Glycol-modified stands for the G.

PET caters to different kinds of packaging for solid food to liquids. It is mostly found in soft drinks, sport drinks, bottled water, salad dressing, vegetable oil containers and peanut butter containers.

HDPE (High-Density Polyethylene)

HDPE is found in milk and juice packaging in supermarkets, syrup containers and even grocery bags, and is 100% recyclable. It is lightweight yet strong – a HDPE milk jug that weighs 2 ounces when empty is able to hold a full gallon of milk without breaking or deforming.

PP (Polypropylene)

PP is a stiff plastic that is mostly used to package yogurt, cream cheese, sour cream and to make bottles for prescription drugs. Due to its high melting point, PP is suitable for food packaging products that are microwaveable and dishwasher safe.

HIPS (High-Impact Polystyrene)

This is basically a tougher version of polystyrene (which are the foam cups you see in some smaller takeaway coffee places), and is non-toxic and odorless. Research has shown that using HIPS food packaging in eating establishments is more hygienic than washing and drying utensils, saves labor, electricity and water costs.

Final Thoughts

Lots to consider on whether 3D printed PLA filament is food safe or not. You can also check the manufacturer’s Material Safety Data Sheet to better understand whether the filament has toxic particles.

In the end, if you do 3D print items that’ll touch food, be sure to use PLA food safe coating during finishing. You’ll also want to check to see if the PLA filament has expired or not as well.

If you’re looking to make money by 3D printing objects that’ll touch food, do be sure to think about use cases and how harmful the object could be.