There is a wide variety of 3D printer filaments out there today. If you’re a beginner to 3D printing and just getting started, the sheer number of available filament types out there can be overwhelming. Actually, it can be overwhelming for all skill levels.

Different types of filament will have different printing techniques and use cases. Whether you’re prototyping, printing toys for the kids, or want printed parts for industrial applications, you’ll want to understand the support materials for your printed parts.

I’ll take a look at three of the most used plastic filaments today, PETG vs PLA vs ABS, and how they compare so you can understand what filament to use in your printing process.

What is 3D Printer Filament

Let’s first understand what 3D printer filament is because that’s the 3D printing material you’re using to 3D print your 3D design files.

3D printer filament is a Thermoplastic Polymer, which is a type of plastic with the chemical properties to be heated to soften, molded to different shapes, and cooled to harden again.

There is a wide world of thermoplastics with a dizzying variety of names and acronyms like polylactic acid, thermoplastic elastomers, PET, PVA, CPE, ABS..the list can definitely go on.

If you’re starting to get really confused at this point – don’t worry.The only thing you need to remember is that 3D printing filament is what you need to feed your 3D printer in order to produce your 3D printed objects – it’s that simple.

There are only a few filament types of 3D printer filament you really need to know about, as these are the most commonly used and widely available.

PLA, also known as polylactic acid, is a plant-based thermoplastic which is widely known in the 3D printing community as the go-to filament for any kind of project.

ABS is the same filament used to make lego bricks, and is known to be highly durable. If you’ve ever stepped on a lego brick, you’ll probably agree.

PETG is a popular in-between material that is more flexible than PLA, yet easier and quicker to print than ABS.

Let’s take a closer look at each of these filaments below.

PLA Printer Filament

PLA (polylactic acid) is one of the most popular 3D printing filaments in the world for its versatility and ease of use in 3D printing FDM / FFF. It’s also one of the stronger filaments with good tensile strength, so it’s widely used.

PLA is a completely biodegradable thermoplastic, being made out of organic materials such as corn, potatoes, sugarcane and cassava. PLA filament comes in all sorts of colors and styles that fits a variety of 3D printing applications – you’re sure to find a shade of PLA that fits the project you’re making.

However, PLA’s biodegradable nature doesn’t mean that it simply breaks down naturally in a normal home backyard compost pile. PLA needs to be sent to commercial composting facilities in order to be processed properly.

PLA’s largest advantage is its low handling temperatures (180-210ºC)and lack of odor while printing. Out of the three printing materials, it has the lowest temperature range needed for printing compared to ABS (highest temperature range) and PETG.

With the low handling temperature, PLA is the most bendable and usable for many different types of prints. The filament flow when printing is well suited for better detail like sharp corners. The low temperature and flow allows for high print speeds with PLA as well.

However, with the low heat resistance, that means PLA prints are more susceptible to deformations and warping when exposed to high temperatures and direct sunlight. So you’ll want to control how your prints are stored.

PLA is usually the cheapest of the different filament types, so that also makes it the most used filament for 3D printing. It’s the best filament to start out with when you’re just getting into 3D printing.

PLA Pros

- Easiest filament material to use

- Low heat resistant filament

- Comes from renewable sources

- Compostable at commercial compost facilities

- Non-toxic when incinerated

PLA Cons

- Prints are more susceptible to sunlight and high heat

- Growing raw materials requires significant amount of land

- Risk of contaminating recycling processes if not disposed properly

ABS Printer Filament

Acrylonitrile Butadiene, acronym ABS – is commonly grouped with PLA to make two of the most popular forms of 3D printer filament you can get on the market today. ABS is on the opposite side of the filament spectrum with heat though.

ABS is a high heat-resistant filament material (up to 250ºC). Printing to finish through sanding, glueing or using acetone to create a glossy finish, much like an injection-molded products.

ABS will give you the most durable prints with its high strength impact resistance. That’s one reason it’s used in consumer goods like Lego blocks. That’s a good thing as I think about what Legos go through in the hands of my kids.

When using ABS for 3D printing, it is recommended to have a heated print bed, as the bottom corners of products made out of ABS tend to curl upwards at the final stages of printing.

As a safety note, print in a well-ventilated area for your ABS printing activities. ABS produces a highly unpleasant smell, similar to that of acid burning plastic when it’s being printed. Go in the garage, the workshop in the backyard, or in a separate room in the house – just keep your doors and windows open.

Pros

- Highly impact resistant

- Great flexibility

- Higher melting point

Cons

- Heated print bed required

- Not food safe

- Smells bad!

PETG Printer Filament

PETG stands for Polyethylene Terephthalate Glycol-modified and is a variant of PET, the most used plastic in the world. PET is found in everything from water and soft drink bottles to your takeaway containers.

PETG is a clear plastic because of the G. The Glycol that is added into this filament causes it to be more transparent and translucent, less brittle, more resistant material, and much easier to use. PETG produces smooth finish products, so it’s popular with those who want that glossy look.

PETG is thermoformable and vacuum-formable – meaning that it can tolerate enormous amounts of pressure without cracking or splitting. Because of its rigid structure, it survives harsh sterilization processes and can be used in a variety of medical and pharmaceutical applications.

Like ABS, PETG is a high temperature filament (up to 250ºC), but easier to work with. PETG can have sticky or stringing problems, which reduces the level of detail on your finished product. It is also a recyclable material.

PETG is a good middle-ground filament between PLA and ABS. PETG is a durable and heat-resistant material like ABS, while being easy to print with like PLA.

PETG Pros

- High strength, yet easy to shape

- Good resistance to weather elements like rain, cold, and sun heat

- Great layer adhesion

- Recyclable

- Low risk of warping

- Affordable

PETG Cons

- High printing temperature might damage hot ends

- Risk of stringing during printing

What are the Most Popular 3D Printer Filaments?

When it comes to 3D printer filaments, most people would pick ABS and PLA as their first choice of filament. They’re cheaper and easier to acquire. You can find solutions online to almost any issue you face when printing with these filaments. 3D printing forums and websites are chock-full of experienced ABS and PETG users willing to help.

What’s the Strongest 3D Printer Filament?

PETG is the strongest filament compared with PLA second and ABS third. Polycarbonate is the strongest filament type out there with a tensile strength of 9,800 psi. In a strength test, polycarbonate was able to suspend 685 pounds from a 3D-printed hook. That’s some serious tensile strenght.

What’s the Most Flexible 3D Printer Filament?

The most versatile and flexible filament available is PLA. It has a good mix of all the best things that a 3D printing filament can provide.

Beginners to 3D printing can literally hit the ground running with PLA, building prints from their digital designs with high dimensional accuracy. PLA is stiff, strong and has a long shelf life (if kept away from heat and sunlight).

PLA is also highly affordable – which is what makes it the preferred choice of 3D printing filament for 3D printing enthusiasts worldwide!

What’s the Melting Point Temperature for Filament?

PLA has a glass transition temperature (or melting point) of 55-60ºC, while ABS’s glass transition temperature is higher at 105ºC. PETG’s glass transition temperature stands at 80ºC, which is lower than ABS but higher than PLA.

Where to Buy 3D Printer Filament?

You can easily find any filament you need for your projects through specialty online retailers such as 3dxtech, Push Plastic, and Atomic Filament.

My preferred way though is usually just going to Amazon. There are many sellers, including the filament brands who will sell direct through Amazon. It’s also the easiest way to compare prices.

How Long Does a 3D Printer Filament Spool Last?

Each person has a different consumption rate. Some may be churning out big 3D prints daily, factory style – while others may be less frequent with their use of the 3D printer and the filament which it uses.

3D printer filament usually comes in 1 kg spools. If you print larger projects like cosplay items and big 3D objects, then a single 1 kg roll of filament will not last you more than a couple of days.

If you’re a D&D or board game kind of person and only use up your filament to 3D print miniatures, characters or small terrain highlights, then your filament will last for much longer.

The degradation of your filament also plays a huge part in how long your filament can last you. If stored incorrectly, the lifespan of your filament greatly reduces and you’ll end up with some unusable filament. Expired, old, or poor quality filament produces poor quality prints.

As a general rate, expect to spend around 166 hours of printing for every 1kg roll of filament you have before it runs out.

Final Thoughts PETG vs PLA vs ABS

In an ideal world, there would be one filament that does everything you want and solves every problem you might have with 3D printing.

Unfortunately, there is no “one filament to rule them all.” It’s all up to personal preference and what you want to print. Different types of filament have their advantages and disadvantages depending on the desired finished product.

If you’re a beginner to the world of 3D printing, I’d recommend starting with the basics of PLA for your first few projects. Once you get more comfortable with the entire printing process and have the basics down, test other filaments and even mixing and matching to create functional parts of your projects.

Do research on what you want to print and see what filaments offer the best support structures for you. There are many existing concepts out there that you can learn from.

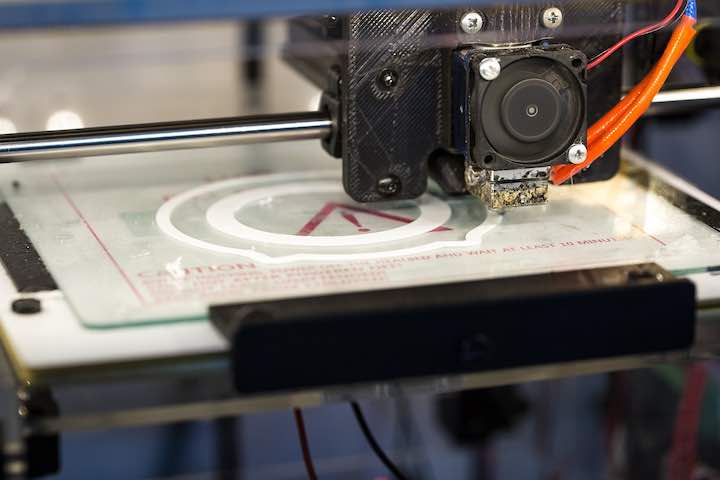

Photo Credit: “3D Printing at NASA” by Lukas Schlagenhauf is licensed under CC BY-ND 2.0.